CASE STORY 18-07

Placing bets on additive manufacturing with innovation loops

Additive manufacturing is growing as an engine for growth and innovation in many industries. Our client sees their valuable aftermarket business threatened by technology that allows customers to produce their own spare parts. But they also see opportunities within mass customization, increased part functionality and supply chain realignment. The question is where to be creative, how to act and what ideas to file into patents?

“Our aftermarket business is dying but who dares to talk about it?”

The challenge

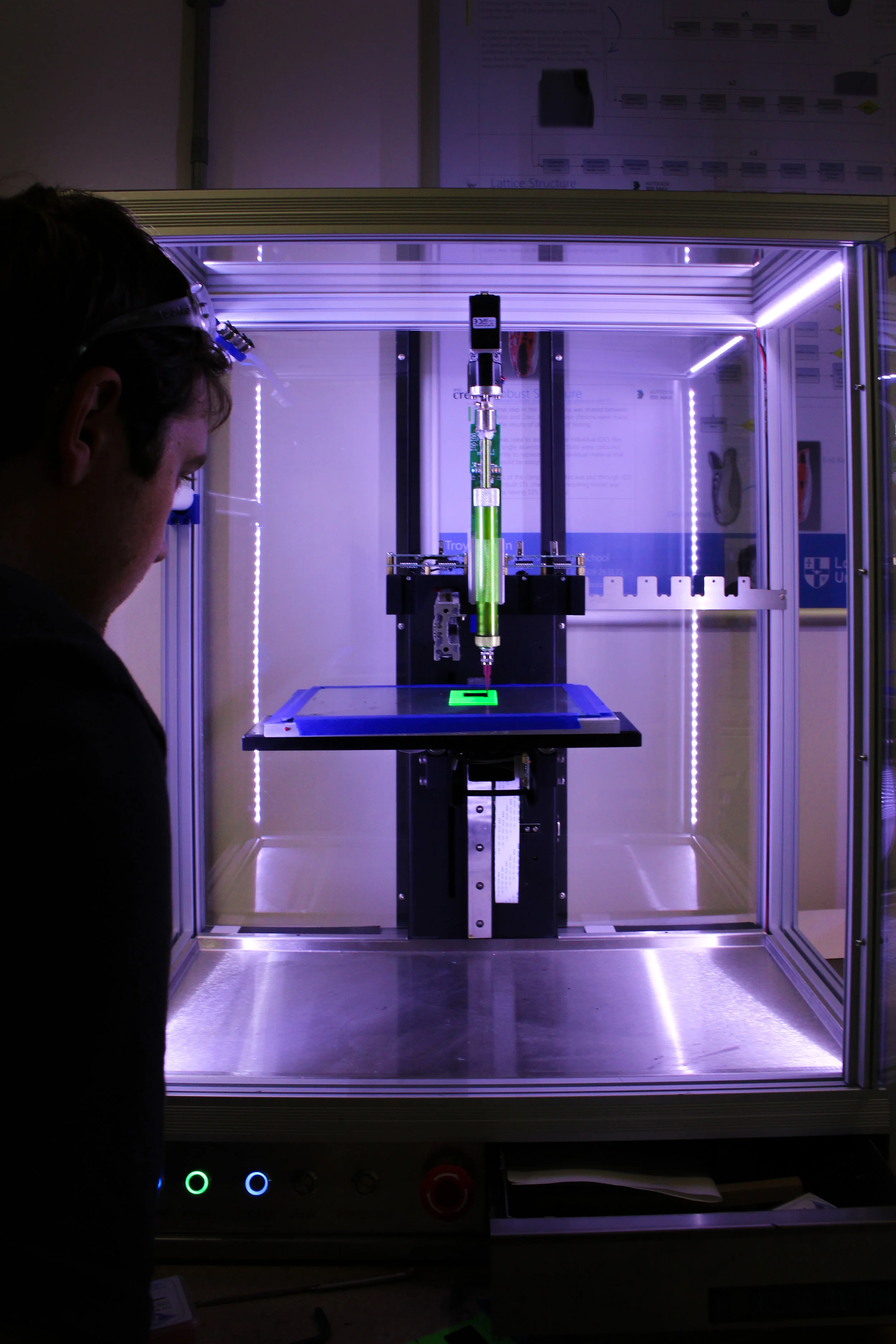

In this project we wanted to explore how to offer a superior service enabled by 3D-printing, prototype solutions within that space and protect strategic ideas in patents.

Project setup

Together with scope, limitations, participants and time plan we conducted a research in three blocks; the data, the vision and the story. Benefits of having Pollen drive the project include speed, state-of-the-art methodology, white labeling and external competence involvement.

The data

Investigate available and emerging technologies, prior art and competitors strategies.

The vision

To understand where to bet on the future, we study the past. A very relevant analogy was built around the history of Spotify. Maybe going from physical part to digital CAD-file is a bit like moving from a CD to streamed music. Focus: Make it better than free.

The story

What are people doing today and what might they do tomorrow. Through a powerful story from a real customer the project got the sense of urgency it needed.

“Pollen help us challenge our assumptions, see new data through white-label research and professionally facilitate a creative process. ”

3 loops with different topics

Our three phase iterative innovation process was used to give structure to the creative process. In this project we did three loops through aim, think, do. We work in iterations in order to minimize risk and maximize learnings by looking placing bets in complementary concepts and looking at the challenge from different perspectives.

AIM - What problems and opportunities do we see?

After setting the topic for the loop and what questions to investigate, we got out of the house. We observed users, interviewed experts and gathered data in order to fully understand the problem. New data is found since Pollen explores without exposing the client brand.

THINK - What solutions is there?

In creative workshops chosen participants worked both on extracting frictions and generate solutions. We use association, false interpretation, inspirational examples and random input to diverge into new ideas.

DO - How do we find out what’s best?

Top ranked ideas were developed and key assumptions tested with stakeholders. New insights lead some ideas into new directions and closed others.

The results

The project ran over 5 months and during that time we completed 3 loops, each handling specific challenges for different stakeholders. The project resulted in 6 filed invention disclosures around additive manufacturing so far, and the launch of 3 pilot projects to further investigate the concepts. But maybe most important is how the project strengthened innovation culture in the team, generated new learnings and created motivation and commitment to climb up on the pink elephant of diminishing aftermarket business.

68 documented ideas

6 filed invention disclosures

3 launched pilot-projects